Environment

- Initiatives

(Disclosures based on

the TCFD framework) - Initiatives

(Reduce CO2 emissions) - Initiatives

(Appropriate Water Usage)

Approach and Policy

The Takara Group positions the harmonization of its business activities with global environmental preservation as one of its key challenges, and contributes to building a sustainable society by establishing and continuously improving the environmental management system.

- 1.We comply with laws and regulations related to the environment, in addition to other requirements that we have agreed to.

- 2.In the course of the Takara Group’s business activities, we place particular emphasis on the following items.

①We strive to prevent environmental pollution.

②We strive to promote energy and resource conservation, and try to use sustainable resources.

③We strive to reduce greenhouse gas emissions and mitigate climate change.

④We support and promote activities related to biodiversity and ecosystem protection and preservation.

⑤We strive for environmentally conscious product development, including promoting the 3Rs* for containers and packaging.

- 3.We actively disclose information on our environmental initiatives and environmental performance, while striving to communicate with society.

- 4.While using education and awareness programs to convey this Environmental Policy to all members of the Takara Group, we also energetically support employees’ participation in social contribution activities.

*3Rs: Reduce, Reuse, and Recycle

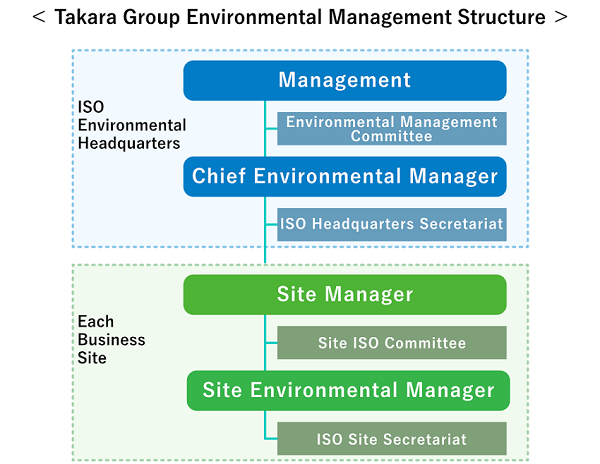

Structure

Established an environmental management system based on ISO 14001

100% of Takara Shuzo's production bases (all factories) and Takara Shuzo Head Office (including Takara Holdings and Takara Shuzo International Headquarters) have acquired ISO14001 certification. Centered on the ISO Environmental Headquarters, we are working toward goals directly linked to management.

Targets

| Initiative themes | Specific measures | Targets |

|---|---|---|

| Response to climate change issues | Reduction of CO2 emissions |

FY2025 [Takara Bio ] - Reduce CO2 emission intensity (CO2 emissions per net sales) by 50% compared with FY2018. FY2030 [ Takara Shuzo / Takara Shuzo International ] - Reduce CO2 emissions at production sites by 46% compared with FY2018. [Takara Shuzo (Distribution) ] - Reduce CO2 emission intensity (CO2 emissions per shipping volume) from shipping Takara Shuzo products by 10% compared with FY2018. FY2050 [ Entire Group ] - Achieve net zero CO2 emissions in the Takara Group on a consolidated basis. |

| Appropriate water usage | Water usage that considers local characteristics |

[ Takara Shuzo ] - Reduce units of water usage (water usage per production volume) of Takara Shuzo by 15% compared with FY2017 by FY2025. - Continue initiatives to protect water sources and conserve wastewater. |

| Limiting waste generation | Reduce plant waste volume and promote recycling |

[ Takara Shuzo ] Continue reusing 98% or more of waste generated in Takara Shuzo’s production processes. |

| Initiatives to reduce food loss |

[ Takara Shuzo ] - Improve the effective use rate of raw materials such as scarce Japan-produced fruits. - Drive efforts to increase the life of Takara products and the processed foods that use them. |

|

| Response to environmentally conscious product packages and packaging | Develop environmentally conscious products |

[ Takara Shuzo ] - Facilitate the introduction of sustainable containers and packaging that consider the 3Rs, and achieve 100% adoption by FY2050. - Facilitate the use of paper with forest protection certification in paper carton products, and achieve 100% adoption by FY2030. - Facilitate the use of biomass ink in paper and plastic labels, and achieve 100% usage by FY2025. [ Takara Shuzo International ] - Maintain the development of and transition to products with reduced plastic volume in accordance with laws and regulations of foreign countries. [ Takara Bio ] - Facilitate the use of paper with forest protection certification in paper carton products, and achieve 100% adoption by FY2025. - Facilitate the use of aluminum-free packages in one-sided aluminum pouches, and achieve 100% adoption by FY2025. - Facilitate the use of vegetable oil-based ink in paper packages, and achieve 100% usage by FY2025. |

| Free distribution of booklets to raise awareness on recycling |

[ Takara Shuzo ] Continue distributing free to those who are interested. |

|

| Preservation of ecosystems and biodiversity | Assistance for activities and research protecting ecosystems and biodiversity |

[ TAKARA HOLDINGS INC. ] - Continue assistance through the Takara Harmonist Fund. [ TAKARA HOLDINGS INC. / Takara Shuzo ] - Continue activities at business sites that contribute to local communities. |

Related SDGs

Initiatives

Disclosures based on the TCFD framework

The Takara Group positions the harmonization of its business activities with global environmental preservation as one of its key challenges, and is actively implementing these initiatives.

The Group recognizes that climate change is an important issue that affects the sustainability of our business, and we support the recommendations of the Task Force on Climate-related Financial Disclosures (TCFD). We will continue to assess and respond to the risks and opportunities related to climate change in line with the TCFD framework, disclose relevant information, and engage in dialogue with our stakeholders.

Additionally, our company is a member of the TCFD Consortium, a forum where companies and financial institutions that support the TCFD recommendations collaborate to promote initiatives, support effective corporate information disclosure, and facilitate appropriate investment decisions by financial institutions. Our group's climate change policy aligns with the policies of the TCFD Consortium.

Response to climate change

Formulating a roadmap to reduce CO2 emissions

The Takara Group has set CO2 emissions reduction targets in its Sustainability Vision and is working to reduce them.

|

Year achieved |

Scope |

Reduction target |

|---|---|---|

| FY2030 | Takara Shuzo Co., Ltd.+Takara Shuzo International Group |

Reduce CO2 emissions at production sites by 46% (compared with FY2018). |

| FY2025 | Takara Bio Group |

Reduce CO2 emission intensity (CO2 emissions per net sales) by 50% (compared with FY2018). |

| FY2050 | Entire Group |

Net zero CO2 emissions |

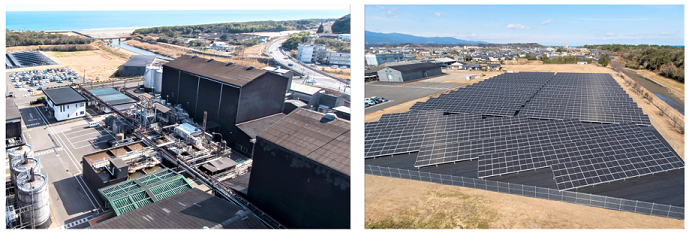

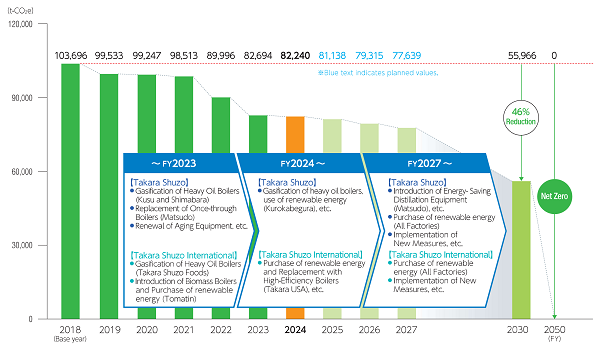

In 2021, under the "Takara Group Sustainability Vision," we established emission reduction targets aligned with the Paris Agreement and the Japanese government's emission reduction goals: "a 46% reduction in CO2 emissions by 2030 and net zero by 2050." In 2022, we formulated an emission reduction plan that included measures such as the use of gas boilers and the introduction of solar panels. In 2024, we enhanced the emission reduction plan by adding measures such as the use of CO2-free electricity and the introduction of energy-saving equipment to increase its effectiveness.

This reduction plan will be continuously updated to always implement the best initiatives for reducing, controlling, and improving the efficiency of energy use, in response to environmental changes and technological developments, aiming to realize a decarbonized society.

○CO2 Emissions Reduction Targets and Plan (Scope 1 and 2) for Production Sites

of Takara Shuzo and Takara Shuzo International Group

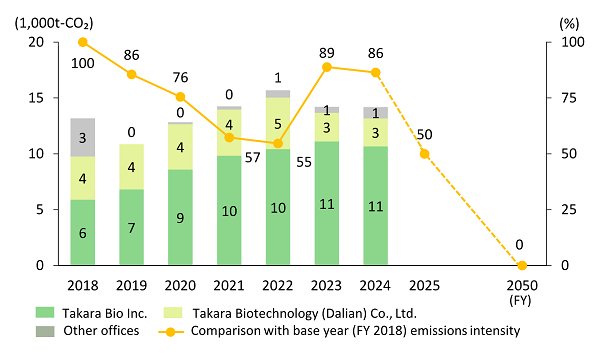

○Takara Bio Group's CO2 Emission Reduction Targets per Unit of Production

for Production Sites (Scope 1 and 2)

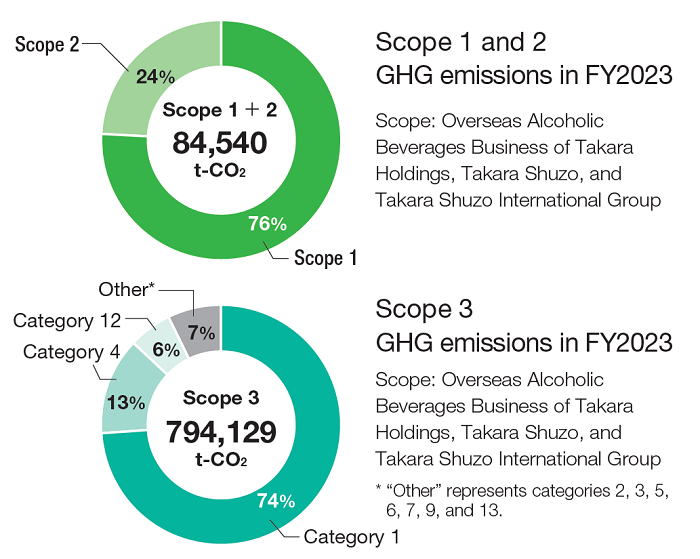

Calculation of greenhouse gas (GHG) emissions across the entire supply chain

-

To help realize a decarbonized society, the Takara Group is working to track GHG emissions not only under Scope 1 and Scope 2, but also under Scope 3. For fiscal 2023, emissions under all three scopes were calculated for the Overseas Alcoholic Beverages Business of Takara Holdings, Takara Shuzo, and Takara Shuzo International Group.

In order to continue monitoring GHG emissions across the Takara Group, we plan to broaden the calculation scope to cover overseas Japanese food wholesalers and related companies.

-

Obtained third party certification for calculation of GHG emissions

Third-party certification was obtained from the JMASusC, an independent verification organization, for the calculation of Scope 1, 2, and 3 emissions in fiscal 2023 at Takara Holdings, Takara Shuzo, and the overseas production sites of the Takara Shuzo International Group.

Reduce CO2 emissions from production process

-

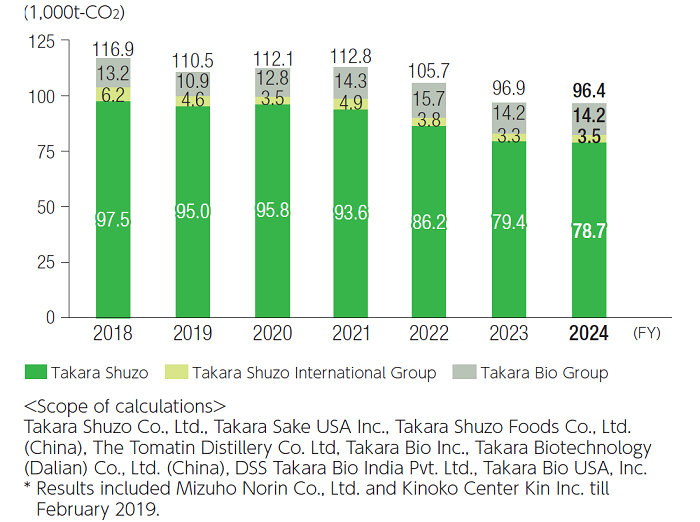

The Takara Group’s total CO2 emissions in production processes for fiscal 2024 was 96,400 t-CO2, a 0.5% year-on-year decrease and a 17.5% decrease from fiscal 2018. As the production processes at Takara Shuzo account for over 80% of the Group’s total CO2 emissions, various measures have been implemented, including updating to high-efficiency once-through boilers, converting boiler fuel from heavy oil to LNG at all plants, and installing solar panels, along with optimizing the operation of production equipment. As a result, CO2 emissions were 78,700 t-CO2, down 0.8% from the previous fiscal year.

Examples of initiatives to reduce CO2 emissions from production processes

- Installing high-efficiency gas boilers, converting the heavy oil boiler to a gas boiler, and other energy-saving equipment

- Introduction of renewable energy

- Purchase of electricity derived from renewable energy

-

Changes in CO2 emissions

from the Takara Group’s production processes

| Achieving 100% renewable energy for electricity usage and converting steam boiler fuel to LNG. |

|---|

|

-

Reduce CO2 emissions from transportation processes

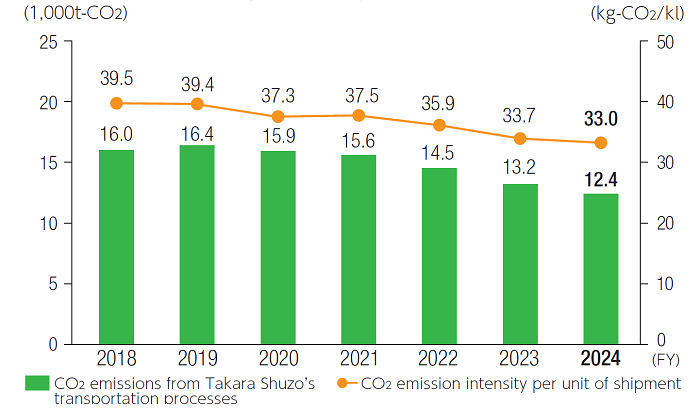

At Takara Shuzo, we are promoting high-efficiency transportation and reduction of reshipments, energysaving vehicle operations, and modal shifts, improving loading efficiency for products shipped by truck and tanker, and taking other measures to reduce CO2 emissions during product transportation.

In fiscal 2024, CO2 emissions from transportation processes were 12,400 t-CO2, a 16.5% reduction in CO2 emission intensity (CO2 emissions per unit of shipment) compared to the base year of FY2018.

-

Changes in CO2 emissions and emission intensity

from Takara Shuzo’s transportation processes

Examples of initiatives to reduce CO2 emissions from transportation processes

- Modal shifts to ferries, rail cars, etc.

- Production closer to the area of consumption in order to reduce shipping between east and west bases

- Developing high-capacity cargo trucks with our transportation subsidiaries

Participation in initiatives to address climate change issues

The Takara Group is participating in the Japan Climate Initiative (JCI) to address climate change issues, and we are continuing to exchange information with companies and various organizations that are actively engaged in climate change countermeasures.

| Expansion of the use of renewable energy. |

|---|

|

| Introduction of electric forklifts and promotion of joint deliveries at Takara Butsuryu System |

|---|

|

| Efforts to reduce methane gas emissions by using rice produced through ”water-saving dry direct seeding cultivation”. |

|---|

|

Appropriate Water Usage

Concepts on Water Resources

The Takara Group promotes energy and resource conservation under the Takara Group Environmental Policy and strives to use sustainable resources. Recognizing the importance of reducing water resource usage to continue using limited water resources sustainably, we will promote the reduction and optimization of water usage.

Reduction of water usage in the production process and the trend of unit consumption.

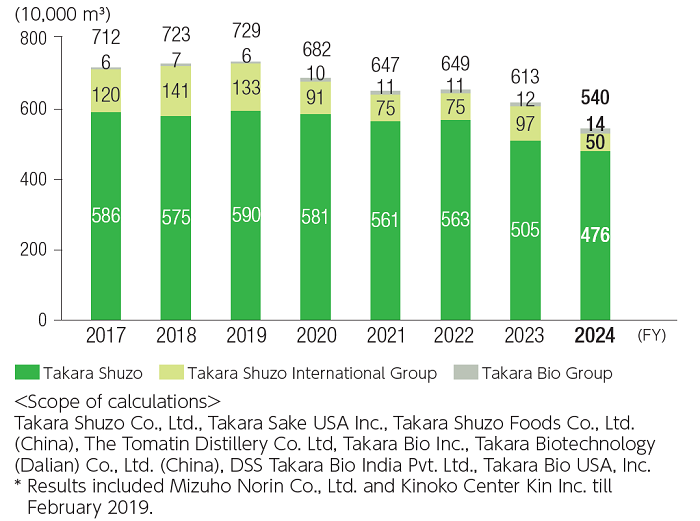

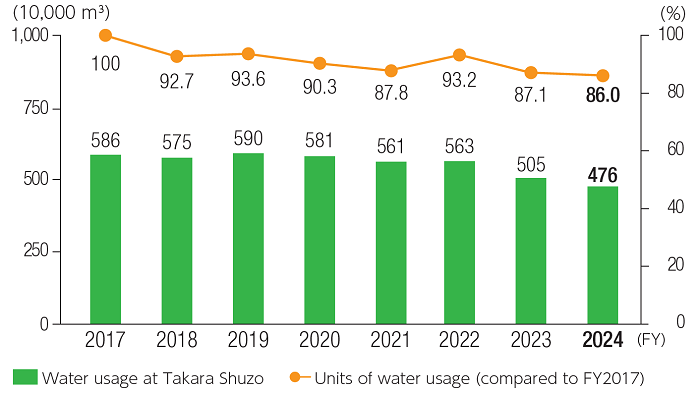

As a result of the installation of water-saving equipment and other measures, the Takara Group’s total water usage for production processes for fiscal 2024 was 5.40 million m3, an 11.9% year-on-year decrease. Takara Shuzo’s units of water usage (water usage per unit of production) decreased by 14.0% from the base year of fiscal 2017.

Changes in water usage in the Takara Group’s production processes

Water usage and units of water usage at Takara Shuzo

Understanding the water stress situation by country where manufacturing sites are located (water risk assessment).

For the Takara Group, water is an essential raw material for manufacturing products. Especially at alcohol production sites, where water usage is high, understanding water stress is considered crucial. Therefore, we utilize the "Baseline Water Stress" evaluation indicator from the Aqueduct Country Rankings developed by the World Resources Institute to assess the water stress situation in the countries where our manufacturing sites are located. As a result, it was found that the water stress is low at eight sites in Japan, the UK, and Canada, while there is moderate water stress at two sites in China and the USA. Additionally, some domestic factories face potential water intake restrictions during droughts and regulations on groundwater usage permits.

Alcohol production sites: 6 locations in Japan, 4 locations overseas.

|

Company Name |

Manufacturing Sites. |

Country Name |

Baseline Water Stress |

number of sites |

|---|---|---|---|---|

|

Takara Shuzo Co., Ltd. |

Takara Shuzo's Factories. |

Japan |

Low - Medium (10-20%) |

6 |

|

Takara Shuzo International Group. |

The Tomatin Distillery Co.Ltd |

United Kingdom |

Low - Medium (10-20%) |

1 |

|

Takara Shuzo Foods Co., Ltd. |

China |

Medium-High(20-40%) |

1 |

|

|

Takara Sake USA Inc. |

U.S.A |

Medium-High(20-40%) |

1 |

|

|

Ontario Spring Water Sake Company |

Canada |

Low - Medium (10-20%) |

1 |

Efforts to Reduce and Optimize Water Usage.

Water is an important resource shared with local communities and ecosystems, and its proper use is required at manufacturing sites. Currently, there are no regions with excessively high water stress in the countries where the Takara Group's manufacturing sites are located. However, to achieve sustainable use of water resources, we are promoting the reduction and proper use of water intake based on the concept of water management (intake and conservation management).

The water sources used at our manufacturing sites are classified into three categories: "tap water," "industrial water," and "groundwater." Regarding tap water, it is used in cooperation with local stakeholders and managed appropriately according to the policies and plans of the local waterworks bureau responsible for intake management. For industrial water and groundwater, each site is the main entity responsible for intake management, and we are actively promoting water conservation and proper use.

Additionally, regarding wastewater from factories, we have established strict voluntary standards that exceed the legally mandated criteria. Using our own wastewater treatment facilities, we purify the water quality before discharging it into sewers, rivers, and oceans. This water purification helps preserve the ecosystems of aquatic organisms.

Prevention of Environmental Pollution.

The Takara Group has established a policy to prevent environmental pollution and is working to prevent environmental pollution at all of its factories. As part of this effort, some of Takara Shuzo's factories have introduced wastewater treatment facilities to prevent river pollution. Furthermore, in addition to reducing emissions of air pollutants, we aim to minimise the discharge of pollutants by implementing appropriate staffing levels and operational management of related facilities, with the objective of reducing environmental risks.We will continue to pursue and advance our efforts to prevent and control environmental pollution.

Examples of Efforts to Reduce and Optimize Water Usage.

●Introduction of Water-Saving Equipment.

At Takara Shuzo Kurokabe Brewery, well water is used for cleaning and cooling manufacturing equipment. By introducing cooling towers in 2021 and 2023, which allow for the repeated use of water, the brewery has reduced its annual water usage by approximately 400,000 tons.

Cooling Tower

●Reuse of Cleaning Water and Cooling Water.

At Takara Shuzo Matsudo Factory, well water is used for the maintenance and management of manufacturing equipment. Since 2000, cleaning water and cooling water have been collected and reused as industrial water. This initiative has reduced annual water usage by 125,000 tons.

● Reuse of Hot Water for Sterilization.

At Takara Shuzo Fushimi Factory, since 2021, hot wastewater from the pasteurizer, which is necessary for sterilizing products, has been collected and reused as feedwater for the boilers used in production equipment. This has reduced annual water usage by 18,000 tons.

Sterilization Equipment and Boilers.

●Reduction of Regional Water Usage through Reuse of Factory Hot Wastewater.

At Takara Shuzo Shimabara Factory, well water is converted into steam using boilers. After being used as steam, the clean hot wastewater is provided to nearby residents for domestic use, contributing to the reduction of regional water usage. Additionally, it is also utilized for heating hot springs and warm water pools.

●Measures for Preserving Brewing Groundwater (Miyamizu)

At Takara Shuzo Shirakabegura, we participate in the “Miyamizu Preservation Research Committee” organized by the Nada Gogo Brewers Association. The Nada Gogo Brewers Association conducts research and studies related to Miyamizu and undertakes activities to minimize the impact of civil engineering works and other factors on groundwater.

Reducing the environmental impact of waste discharge

Approach to Waste Emissions

-

The Takara Group's environmental policy promotes energy and resource conservation, striving for sustainable use of resources.

For example, at “TaKaRa CRAFT”, we strive to reduce waste volumes from the design stage onwards. This involves utilising not only food items discarded due to non-compliance with standards or blemishes, but also typically discarded parts such as fruit peel and seeds after juice extraction. In addition, to promote the circular economy, we are advancing improvements in resource efficiency and reductions in waste emissions. This includes converting food by-products into feed and fertiliser, and reducing the usage of raw materials and packaging materials (such as plastics).

Promotion of a circular economy through reduction and recycling of plant waste

-

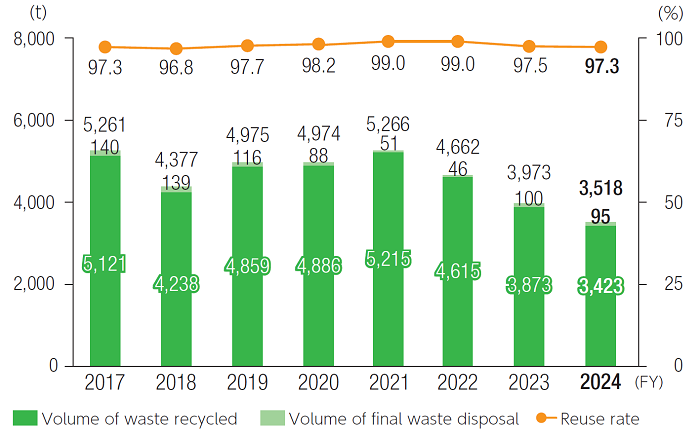

In Takara Shuzo plants, waste products generated include by-products such as shochu lees and other by-products, as well as wastewater treatment sludge, and shipping materials for raw ingredients, containers, etc. As a countermeasure, we are making efforts to reduce the volume of waste generated in our plants by revising disposal routes to enable the sale of industrial waste, repurposing food-based by-products (such as shochu lees) into feed and fertilizer and recycling waste paper from sake cartons. In fiscal year 2024, Takara Shuzo's waste generation was 3,518 tons, with a recycling rate of 97.3% against the target of 98.0%. For fiscal year 2025, we will continue our efforts to reduce waste and promote resource recovery, aiming to achieve the recycling rate target of 98.0%.

Promotion of Plastic Resource Reduction

-

To address various environmental issues such as marine pollution and ecosystem destruction caused by plastics, we are complying with the Act on Promotion of Resource Circulation for Plastics and have set reduction targets for plastic industrial waste and mixed plastic waste at our domestic production sites. In fiscal year 2023, we aimed to reduce waste by more than 1.0% compared to fiscal year 2022. Through initiatives such as shifting to the profitable sale of industrial waste and promoting waste separation, we successfully achieved a 12.7% reduction (32 tons). For fiscal year 2024, we set a target of a 4.1% reduction compared to 2023. However, due to equipment maintenance and updates to production lines, waste increased by 12.8%(28 tons). For fiscal year 2025, we will continue our efforts to reduce plastic resources, aiming for a 15.0% reduction compared to fiscal year 2024.

- Installing equipment for converting shochu lees into feed

- Reducing wastewater treatment sludge

- Conversion of used activated carbon into organic fertilizer through a joint venture with a compost manufacturer (upcycling)

- Reduction of containers through the sale of shochu by weight

- Lightweighting of bottles and cans

- Elimination of labels and stickers

-

Changes in waste generation and reuse rate

at Takara Shuzo

Examples of initiatives for reducing waste products

| Feed production facility |

|---|

|

| Encouraging up-cycling of lees from Sake and Mirin |

|---|

|

Initiatives to reduce food loss

-

Takara Shuzo offers products that use scarce Japan-produced fruits as raw materials.

The fruits have other parts that can be used in a delicious way besides the juice, but most of them are discarded without being used after the juice is pressed. We have developed a technique to extract the taste from unused parts of the fruits such as peels to improve the use rate of Japan-produced fruits, thereby striving to reduce food loss.

Response to environmentally conscious product packages and packaging

Development of environmentally friendly products and reduction of plastics

In Japan, containers and packaging account for approximately 60% (by volume) of waste from households. Takara Shuzo has drawn up Guidelines for Environmentally Friendly Product Development and Procedures for Developing Environmentally Friendly Products, and is working to reduce the use of containers and packaging by procuring materials and developing products that take into account the 3Rs: Reduce, Reuse and Recycle. In addition, Takara Shuzo's own initiative (4Rs), which adds refusing to the 3Rs, is the sale of shochu by the weight. Since its inception in 1998 through March 2025, approximately 10.48 million 2.7-liter plastic bottles have been saved, which corresponds to a reduction of about 3,962 tons of CO₂ emissions that would have been generated during the production and transportation of these bottles.

ISO 14001 environmental targets have been set for the number of these environmentally friendly products developed and the amount of plastic emissions, to promote the reduction of environmental impact.

Initiatives to reduce the environmental impact of containers and packaging

Takara Shuzo is promoting the use of forest certified paper and biomass ink for paper pack products and cardboard for packaging. For bottle and can products, Takara Brewery is also working to reduce the weight of containers and eliminate labels and seals. Takara Bio is promoting the use of aluminium-free reagents in single-sided aluminium pouch packages. We are also promoting the use of forest certified paper and vegetable oil ink for paper packaging.

Through these initiatives, we will continue to reduce the amount of waste and the environmental impact.

| SHOCHIKUBAI SHIRAKABEGURA "Nend" made with rice for sake with controlled methane gas |

|---|

|

Distribution of free recycling awareness booklets

At Takara Shuzo, as part of our recycling awareness activities for children, we have created a picture book called “Recycle Road,” which explains the process of recycling beverage containers through manga-style illustrations. This book is available on our environmental activities website.

Preservation of ecosystems and biodiversity

Our Views on Biodiversity

For the Takara Group, whose business activities are based on the variety of natural bounty - crops, water, and microorganisms - preserving a rich natural environment is the primary prerequisite to continue our business. The Takara Group has formulated the Takara Group Environmental Policy as one of our key management issues for ensuring harmony between environmental conservation and business activities. In the Takara Group Environmental Policy, we position “Promoting and supporting activities related to the conservation and preservation of biodiversity and ecosystems” as a key initiative. In accordance with this Policy, the Takara Group works to preserve a rich natural environment while liaising with external groups even as we strive to preserve biodiversity in a range of aspects within our business.

Participation in TNFD Forum

Takara Holdings considers the harmonization of its business activities with global environmental preservation as one of its key challenges, and has participated in the TNFD Forum, an international forum on the framework for information disclosure under the Taskforce on Nature-related Financial Disclosures (TNFD). Through this participation, we aim to further accelerate the identification of risks and opportunities and the implementation of measures toward achieving nature positive outcomes.

Grants for activities and research to protect ecosystems and biodiversity

Takara Holdings set up the Takara Harmonist Fund, a charitable trust, in 1985, and every year since then has provided grants for activities to protect the natural environment of the forests, plains, and waterside areas of Japan, research to protect the plants and animals that live there, and other activities.

The Takara Group will continue to promote the preservation of biodiversity and rich natural environments by offering assistance to activities and research for protecting and improving Japan’s natural environments.

Presentation Ceremony

“Farm School,” the Takara Shuzo environmental education program

At Takara Shuzo, we have been holding “Farm School,” since 2004. This program is aimed at passing on to the children who will be responsible for the next generation the importance of protecting the natural environment and biodiversity, and to be grateful for nature’s bounty. Targeted at elementary school children and their families, we visit rice paddies in Nantan City, Kyoto Prefecture, three times a year to give them a chance to experience rice growing and to observe nature.

The Takara Group will continue to promote the preservation of biodiversity and rich natural environments by offering assistance to activities and research for protecting and improving Japan’s natural environments.

Nature observation

Initiatives for Environmental Management and Legal Compliance

Environmental Management Syste

ISO 14001 certification has been obtained at all domestic production sites (all six Takara Shuzo plants), as well as at Takara Holdings Headquarters, Takara Shuzo Headquarters, and Takara Shuzo International Headquarters.

ISO 14001 certification accounts for 67% of all Takara Group production sites.

We provide environmental education and training opportunities to employees based on ISO 14001. Additionally, we promote internal awareness for achieving the 'Takara Group Sustainability Vision' by offering education and information on sustainability through the company intranet.

Status of compliance with environmental laws and regulations

In accordance with the ISO 14001 environmental management system, Takara Shuzo complies with all environment-related laws and regulations (including The Fluorocarbon Emissions Control Act,The Act on Promotion of Global Warming Countermeasures, The Energy Conservation Act, and The Water Pollution Prevention Act), and all emissions are below the standard values.We will continue to maintain zero emissions of VOCs, which are one of the causes of air pollution.

We also comply with other requirements agreed upon by the organization and have not been fined or penalized for any environmental law violations in the past three years.

Compliance with Laws and Initiatives on Climate Change

The Takara Group complies with the Energy Conservation Act (Act on the Rational Use of Energy and Conversion to Non-Fossil Energy) and the Act on Promotion of Global Warming Countermeasures, and we appropriately submit all related reports. In addition, we promote our business activities in line with the “Examples of Actions to Address Global Warming” advocated by the Kyoto Chamber of Commerce and Industry, of which we are a member.

Furthermore, based on the Takara Group Sustainability Vision, we have set targets to reduce CO₂ emissions and aim to achieve carbon neutrality by 2050.

Support for Environmental Conservation Activities

In its effort to drive the solution of marine plastic litter issue, a challenge on a global scale, Takara Group has become a member of the Japan Clean Ocean Material Alliance (CLOMA).

The Group is also contributing to actions for environmental conservation by switching the materials for its paper packaging to those certified by FSC, PEFC, and other forest protection certification systems.

Tomatin Distillery named Sustainable Distillery of the Year

at Icons of Whisky Awards 2023

The Tomatin Distillery Co Ltd is delighted to announce that the company was named ‘Sustainable Distillery of the Year’ at the Whisky Magazine’s Icons of Whisky Awards 2023.

The Icons of Whisky Awards, organised by Whisky Magazine, are an annual award in Edinburgh that honours outstanding people, bars, producers and retailers in every sector in the UK.

The Distillery is working with fellow members of the Scotch Whisky Association towards achieving the ambitious target, for the industry, of having net zero emissions※ in our operations by 2040, and this initiative was recognized.

- * By reducing all greenhouse gas emissions, including CO2, to virtually zero, the total amount of emissions minus the amount absorbed and removed is reduced to zero, rather than reducing emissions to zero.

Takara Group Environmental initiatives report

Takara groups's data and activities related to environment can also be found in Takara Group Environmental initiatives report.