Sustainability

Environment

- Initiatives

(Disclosures based on

the TCFD framework) - Initiatives

(Reduce CO2 emissions) - Initiatives

(Appropriate Water Usage)

Approach and Policy

The Takara Group positions the harmonization of its business activities with global environmental preservation as one of its key challenges, and contributes to building a sustainable society by establishing and continuously improving the environmental management system.

- 1.We comply with laws and regulations related to the environment, in addition to other requirements that we have agreed to.

- 2.In the course of the Takara Group’s business activities, we place particular emphasis on the following items.

①We strive to prevent environmental pollution.

②We strive to promote energy and resource conservation, and try to use sustainable resources.

③We strive to reduce greenhouse gas emissions and mitigate climate change.

④We support and promote activities related to biodiversity and ecosystem protection and preservation.

⑤We strive for environmentally conscious product development, including promoting the 3Rs* for containers and packaging.

- 3.We actively disclose information on our environmental initiatives and environmental performance, while striving to communicate with society.

- 4.While using education and awareness programs to convey this Environmental Policy to all members of the Takara Group, we also energetically support employees’ participation in social contribution activities.

*3Rs: Reduce, Reuse, and Recycle

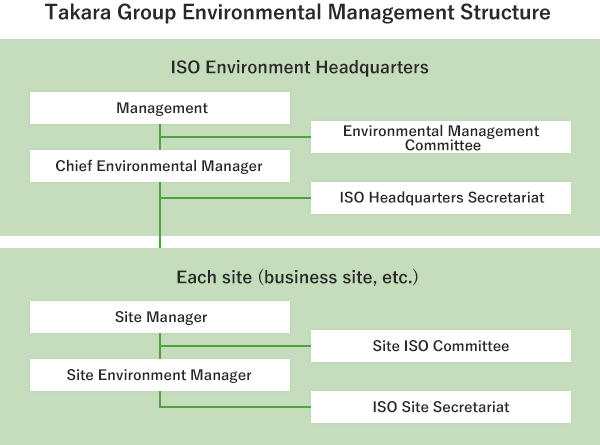

Structure

Established an environmental management system based on ISO 14001

100% of Takara Shuzo's production bases (all factories) and Takara Shuzo Head Office (including Takara Holdings and Takara Shuzo International Headquarters) have acquired ISO14001 certification. Centered on the ISO Environmental Headquarters, we are working toward goals directly linked to management.

Targets

| Initiative themes | Specific measures | Targets |

|---|---|---|

| Response to climate change issues | Reduction of CO2 emissions |

FY2030 [ Takara Shuzo / Takara Shuzo International ] - Reduce CO2 emissions at production sites by 46% compared with FY2018. [Takara Bio ] - Reduce CO2 emission intensity (CO2 emissions per net sales) by 50% compared with FY2018. [Takara Shuzo (Distribution) ] - Reduce CO2 emission intensity (CO2 emissions per shipping volume) from shipping Takara Shuzo products by 10% compared with FY2018. FY2050 [ Entire Group ] - Achieve net zero CO2 emissions in the Takara Group on a consolidated basis. |

| Appropriate water usage | Water usage that considers local characteristics |

[ Takara Shuzo ] - Reduce units of water usage (water usage per production volume) of Takara Shuzo by 15% compared with FY2017 by FY2025. - Continue initiatives to protect water sources and conserve wastewater. |

| Limiting waste generation | Reduce plant waste volume and promote recycling |

[ Takara Shuzo ] Continue reusing 98% or more of waste generated in Takara Shuzo’s production processes. |

| Initiatives to reduce food loss |

[ Takara Shuzo ] - Improve the effective use rate of raw materials such as scarce Japan-produced fruits. - Drive efforts to increase the life of Takara products and the processed foods that use them. |

|

| Response to environmentally conscious product packages and packaging | Develop environmentally conscious products |

[ Takara Shuzo ] - Facilitate the introduction of sustainable containers and packaging that consider the 3Rs, and achieve 100% adoption by FY2050. - Facilitate the use of paper with forest protection certification in paper carton products, and achieve 100% adoption by FY2030. - Facilitate the use of biomass ink in paper and plastic labels, and achieve 100% usage by FY2025. [ Takara Shuzo International ] - Maintain the development of and transition to products with reduced plastic volume in accordance with laws and regulations of foreign countries. [ Takara Bio ] - Facilitate the use of paper with forest protection certification in paper carton products, and achieve 100% adoption by FY2025. - Facilitate the use of aluminum-free packages in one-sided aluminum pouches, and achieve 100% adoption by FY2025. - Facilitate the use of vegetable oil-based ink in paper packages, and achieve 100% usage by FY2025. |

| Free distribution of booklets to raise awareness on recycling |

[ Takara Shuzo ] Continue distributing free to those who are interested. |

|

| Preservation of ecosystems and biodiversity | Assistance for activities and research protecting ecosystems and biodiversity |

[ TAKARA HOLDINGS INC. ] - Continue assistance through the Takara Harmonist Fund. [ TAKARA HOLDINGS INC. / Takara Shuzo ] - Continue activities at business sites that contribute to local communities. |

Related SDGs

Initiatives

Disclosures based on the TCFD framework

The Takara Group positions the harmonization of its business activities with global environmental preservation as one of its key challenges, and is actively implementing these initiatives.

The Group recognizes that climate change is an important issue that has an impact on the sustainability of its business. We will continue to consider and respond to climate change issues in accordance with the framework of the Task Force on Climate-related Financial Disclosures (TCFD), disclose relevant information, and engage in dialogue with stakeholders.

Response to climate change

Formulating a roadmap to reduce CO2 emissions

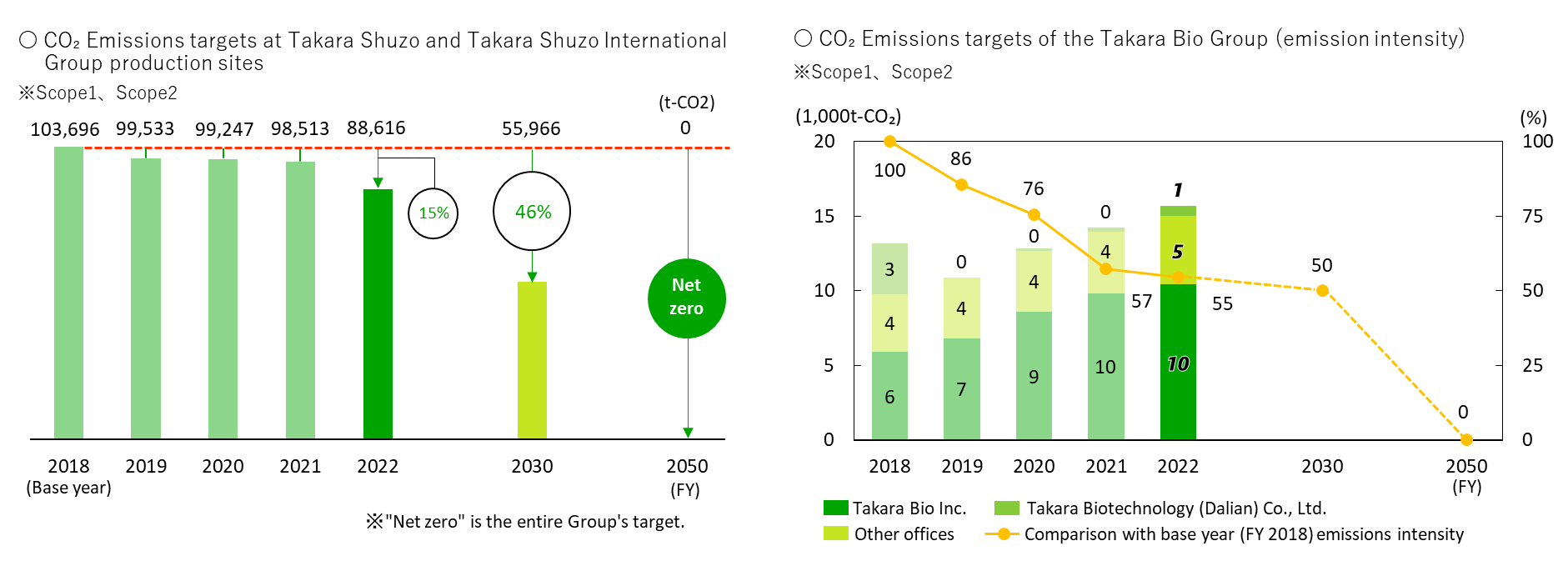

The Takara Group has set CO2 emissions reduction targets in its Sustainability Vision and is working to reduce them.

|

Year achieved |

Scope |

Reduction target |

|---|---|---|

| FY 2030 | Takara Shuzo Co., Ltd. |

Reduce CO2 emissions at production sites by 46% (compared with FY2018). |

| Takara Shuzo International Group |

Reduce CO2 emissions at production sites by 46% (compared with FY2018). |

|

| Takara Bio Group |

Reduce CO2 emission intensity (CO2 emissions per net sales) by 50% (compared with FY2018). |

|

| FY 2050 | Entire Group |

Net zero CO2 emissions |

In June 2022, we formulated a CO2 emissions reduction roadmap and created a plan for measures to reduce emissions. Specific measures include utilization of gas boilers and adoption of solar panels. This roadmap will be updated from time to time in response to environmental changes and technological developments, with the aim of constantly optimizing efforts to reduce or curb energy use and improve efficiency.

Our Responses to Climate Change

Reduce CO2 emissions from production process

-

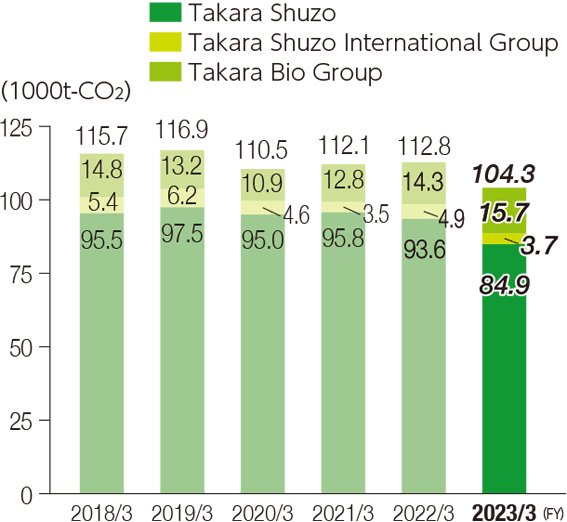

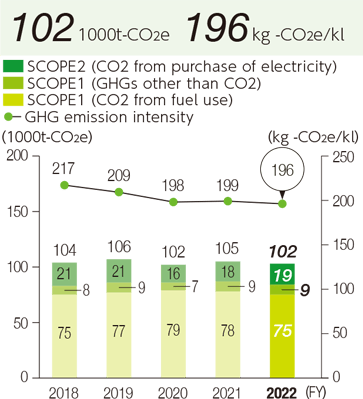

The Takara Group’s total CO2 emissions in production processes for fiscal year 2022 was 104,300 t-CO2, a 7.5% year-on-year decrease. Energy efficiency improved thanks to installing energy-saving equipment and working to optimize heat recovery and equipment usage, such as upgrading to a highefficiency boiler, converting the heavy oil boiler to a gas boiler, and reducing the amount of steam by Reusing waste heat from sterilized hot water.

In addition, in FY2022, Takara International Group's sales volume decreased by 24.5% due to the restoration of Tomatin's biomass boiler, while Takara Bio Group's sales volume increased by 9.7% due to the full-scale operation of the Center for Gene and Cell Processing building 2.

-

Takara Group production processes CO2 emissions

(total emissions)

Changes in CO2 emissions (total emissions) of the Takara Group's production processes

<Scope of calculations>

Takara Shuzo Co., Ltd., Takara Sake USA Inc., Takara Shuzo Foods Co., Ltd. (China), The Tomatin Distillery Co. Ltd., Takara Bio Inc., Takara Biotechnology (Dalian) Co., Ltd.

* Results included Mizuho Nourin Co., Ltd. and Kinoko Center Kin Inc. till February 2019.

Examples of initiatives to reduce CO2 emissions from production processes

- Installing high-efficiency gas boilers, converting the heavy oil boiler to a gas boiler, and other energy-saving equipment

- Reusing waste heat from sterilized hot water

- Promoting the use of co-generation (combined heat and power) system

-

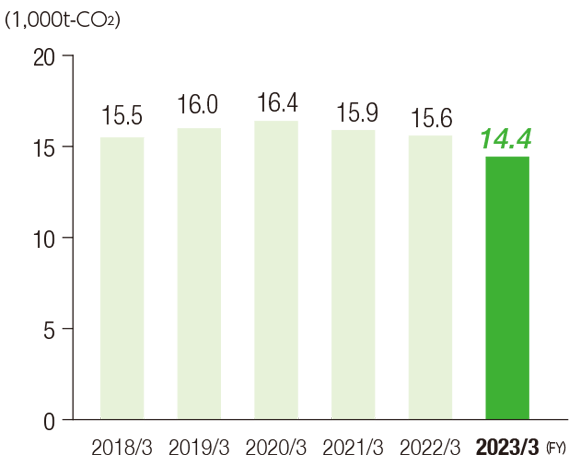

Reduction of CO2 emissions from distribution

At Takara Shuzo, we are promoting high-efficiency transportation, energy-saving vehicle operations, and modal shifts, improving loading efficiency for products shipped by truck, and taking other measures to reduce CO2 emissions during product transportation. In fiscal year 2022, CO2 emissions from transportation processes were 14,400 t-CO2, a 7.7% year-on-year reduction due to the impact of efforts such as improving loading efficiency for products shipped by truck.

-

Takara Shuzo's distribution processCO2 emissions

(total emissions)

CO2 emissions from TaKaRa Shuzo logistics(total emissions)

Examples of initiatives to reduce CO2 emissions from transportation processes

- Modal shifts to ferries, rail cars, etc.

- Production closer to the area of consumption in order to reduce shipping between east and west bases

- Developing high-capacity cargo trucks with our transportation subsidiaries

| Energy for Takara Holdings Corporate History Museum goes 100% carbon-free |

|---|

|

Appropriate Water Usage

Limiting water usage in production processes

-

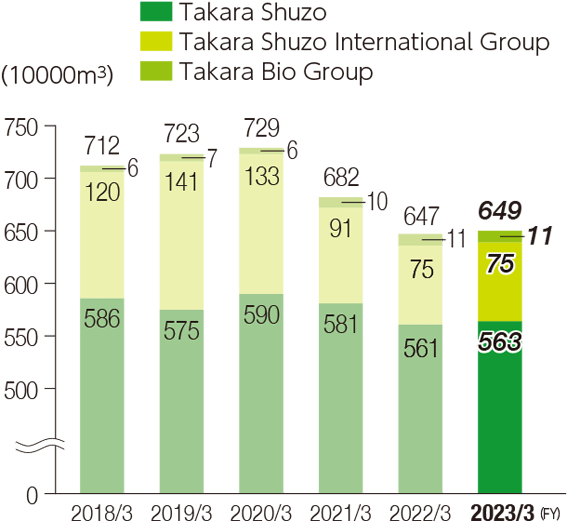

The Takara Group environmental policy states "We will promote energy and resource conservation and strive to use resources in a sustainable manner." As such, we recognize the importance of reducing water consumption in order to continue to use limited water resources in a sustainable manner, and will promote the reduction and optimization of water consumption.

The Takara Group total water use in production processes in FY2022 was 6.49 million m³, an increase of 0.3% from the previous year due to an increase in water use resulting from new product manufacturing operations that began in FY2022.Status of Takara Shuzo’s Legal Compliance Concerning Water Quantity and Quality at the Time of Withdrawal/Discharge

There has been no violation of laws and regulations with regard to withdrawal of water or discharge of wastewater in the past three years.

Takara Shuzo’s Business Activities in Water-stressed Areas

Some of the plants may face restrictions on water withdrawal at a time of water shortage.

Some of the plants are subject to limits on the amount of groundwater that can be pumped.Examples of initiatives to Reduce Water Consumption

- Reduction of washing water by improving cleaning methods for manufacturing equipment

- Reuse of container washing water and cooling water during product manufacturing

-

Water usage in Takara Group production processes

Changes in Water Consumption in the Takara Group's Production Process

<Scope of calculations>

Takara Shuzo Co., Ltd., Takara Sake USA Inc., Takara Shuzo Foods Co., Ltd. (China), The Tomatin Distillery Co. Ltd., Takara Bio Inc., Takara Biotechnology (Dalian) Co., Ltd.

* Results included Mizuho Nourin Co., Ltd. and Kinoko Center Kin Inc. till February 2019.

Limiting Waste Generation

Reduce plant waste volume and promote a circular economy through recycling

-

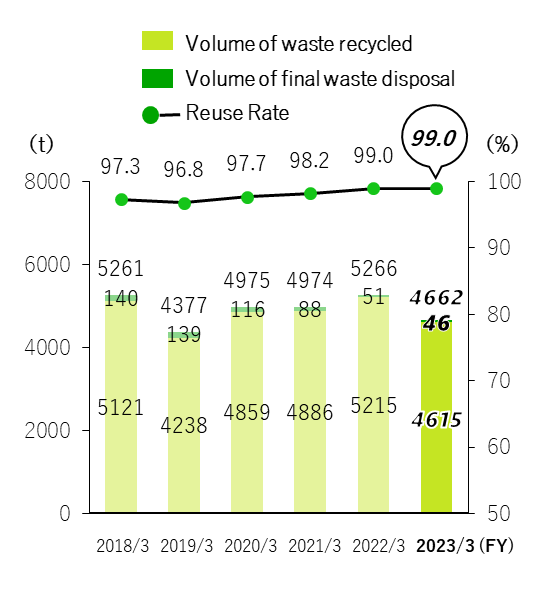

In Takara Shuzo plants, waste products generated include by-products such as shochu lees and the like, as well as wastewater treatment sludge, and shipping materials for raw ingredients, containers, etc. For this reason, we are striving to reduce the volume of waste generated in our plants, which includes continuing to reuse 99% or more of waste, by making efforts to effectively utilize the waste, such as repurposing food-based by-products (such as shochu lees) into feed and fertilizer. The volume of waste generated by Takara Shuzoin fiscal 2022 was 4,661 tons (reuse rate was99.0%), on par with the previous fiscal year.

Examples of initiatives for reducing waste products

- Installing equipment for converting shochu lees into feed

- Reducing wastewater treatment sludge

- Conversion of used activated carbon into organic fertilizer through a joint venture with a compost manufacturer (upcycling)

-

Takara Shuzo's waste generation and recycling rate

Changes in waste emissions and reuse rate of Takara Shuzo

| Feed production facility |

|---|

|

| Encouraging up-cycling of lees from Sake and Mirin |

|---|

|

Initiatives to reduce food loss

-

Takara Shuzo offers products that use scarce Japan-produced fruits as raw materials.

The fruits have other parts that can be used in a delicious way besides the juice, but most of them are discarded without being used after the juice is pressed. We have developed a technique to extract the taste from unused parts of the fruits such as peels to improve the use rate of Japan-produced fruits, thereby striving to reduce food loss.

In September 2021, Takara Shuzo launched Takara Can Chu-Hi Sumika, a not-too-sweet chu-hi with a clean taste of fruit flavors, made from Japan-produced fruits without wasting any part of them. -

Takara Can Chu-Hi Sumika

Response to environmentally conscious product packages and packaging

In Japan, approximately 60% of general household garbage (based on volume) are containers and packaging. In order to address this problem, Takara Shuzo is promoting materials procurement and product development emphasizing the 3Rs (reduce, reuse, recycle). Furthermore, as an independent initiative (4R), Takara Shuzo is selling shochu by weight. Shochu is put into specialized tanks at our plants, then sent directly to retail stores, where customers bring plastic PET bottles, etc. from home and fill the exact amount they need from the specialized tanks when making a purchase.

Since this allows customers to buy only the volume they need without purchasing a container, it translates to resource conservation and less garbage.

From 1998, when these efforts started, to the end of March 2023, we have been able to conserve the equivalent of approximately 10.18 million 2.7-liter PET bottles.

Also, in order to address various environmental issues surrounding plastics, such as marine pollution, we are targeting a 1% annual reduction of plastic industrial waste and mixed plastic waste at our production sites in Japan, including compliance with the Law for Promotion of Recycling of Plastic Resources.

Development of environmentally friendly products

Takara Shuzo has created guidelines such as “Guidelines for the Development of Environmentally Friendly Products” and “Procedures for Environmentally Conscious Product Development.” We have also set environmental targets based on ISO 14001 for material procurement and product development, and we are continuously promoting product development that considers the 3Rs (Reduce, Reuse, Recycle) for containers. For paper pack products and packaging cardboard, we promote the use of certified forest paper and biomass inks. For bottle and can products, we are working on container weight reduction and the elimination of labels and stickers.

Takara Bio is promoting a switch from single-sided aluminum pouches to aluminum-free pouches. It is also promoting the use of certified forest paper and vegetable oil ink for paper packaging.

| SHOCHIKUBAI SHIRAKABEGURA "Nend" made with rice for sake with controlled methane gas |

|---|

|

Distribution of free recycling awareness booklets

At Takara Shuzo, as part of our recycling awareness activities for children, we have created a picture book called “Recycle Road,” which explains the process of recycling beverage containers through manga-style illustrations. This book is available on our environmental activities website.

Preservation of ecosystems and biodiversity

Assistance for activities and research protecting ecosystems and biodiversity

-

Takara Holdings established the Takara Harmonist Fund in 1985, and ever since has carried out annual activities for protecting Japan’s forests, grasslands, and aquatic environments, in addition to offering assistance for research and other efforts toward safeguarding the wildlife in these habitats. The selection of recipients of assistance is carried out by a steering committee comprised of experts specialized in the natural sciences.

In fiscal year 2023, 10 activities and studies related to the conservation of the natural environment, including “Factors contributing to the decline of The Hirundo daurica during the breeding season,” were selected from a large number of applications. During 38 years of the program, a cumulative total of 194,461,000 yen has been granted to 411 recipients. -

Hirundo daurica

Presentation Ceremony

Environmental Management System

ISO 14001 certification has been obtained at all domestic production sites (all six Takara Shuzo plants), as well as at Takara Holdings Headquarters, Takara Shuzo Headquarters, and Takara Shuzo International Headquarters.

ISO 14001 certification accounts for 67% of all Takara Group production sites.

Status of compliance with environmental laws and regulations

In accordance with the ISO 14001 environmental management system, Takara Shuzo complies with all environment-related laws and regulations (including The Fluorocarbon Emissions Control Act,The Act on Promotion of Global Warming Countermeasures, The Energy Conservation Act, and The Water Pollution Prevention Act), and all emissions are below the standard values.

We also comply with other requirements agreed to by the organization, and there were no penalties or fines for violations of environmental laws and regulations in the fiscal year ended March 31, 2023.

Support for Environmental Conservation Activities

In its effort to drive the solution of marine plastic litter issue, a challenge on a global scale, Takara Group has become a member of the Japan Clean Ocean Material Alliance (CLOMA).

The Group is also contributing to actions for environmental conservation by switching the materials for its paper packaging to those certified by FSC, PEFC, and other forest protection certification systems.

Tomatin Distillery named Sustainable Distillery of the Year

at Icons of Whisky Awards 2023

The Tomatin Distillery Co Ltd is delighted to announce that the company was named ‘Sustainable Distillery of the Year’ at the Whisky Magazine’s Icons of Whisky Awards 2023.

The Icons of Whisky Awards, organised by Whisky Magazine, are an annual award in Edinburgh that honours outstanding people, bars, producers and retailers in every sector in the UK.

The Distillery is working with fellow members of the Scotch Whisky Association towards achieving the ambitious target, for the industry, of having net zero emissions※ in our operations by 2040, and this initiative was recognized.

- * By reducing all greenhouse gas emissions, including CO2, to virtually zero, the total amount of emissions minus the amount absorbed and removed is reduced to zero, rather than reducing emissions to zero.

Takara Shuzo's GHG emissions and emission intensity

Takara Group Environmental initiatives report

Takara groups's data and activities related to environment can also be found in Takara Group Environmental initiatives report.